Form

This specification covers Aerospace using Alpha-beta 6Al-4V Titanium alloy in the form of bars, wire, forgings, flash welded rings, drawn shapes, and stock for forging or flash welded rings.

Chemical components(%)

Composition | C | O | N | H | Fe | Al | V | Y |

Min | \ | \ | \ | \ | \ | 5.50 | 3.50 | \ |

Max | 0.08 | 0.20 | 0.05 | 0.0125 | 0.30 | 6.75 | 4.50 | 0.005 |

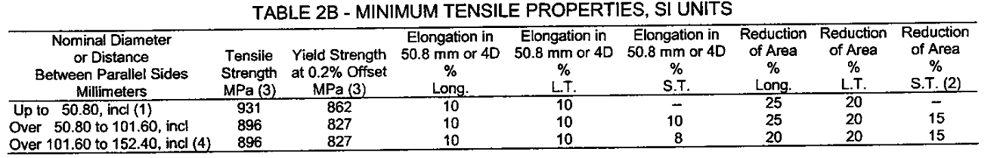

Tensile properties

Condition

Bars

Hot finished with or without subsequent cold reduction, annealed, and descaled. Unless prohibited by purchaser, bars may be solution heat treated before annealing. The product shall be produced using standard industry practices designed strictly for the production of bar stock to the procured thickness. Cut plate shall not be supplied in lieu of bar.

Wire

Cold drawn, annealed, and descaled.

Forgings and Flash Welded Rings

Annealed and descaled. Unless prohibited by purchaser, product may be solution heat treated before annealing.

Flash welded rings shall not be supplied unless specified or permitted on purchaser's part drawing. When supplied, rings shall be manufactured in accordance with AMS 7498.

Drawn Shapes

Drawn, annealed, and descaled! Unless prohibited by purchaser, drawn shapes may be solution heat treated before annealing.

Stock for Forging or Flash Welded Rings

As ordered by the forging or flash welded ring manufacturer.

Heat Treatment

Bars, wire, forgings, and flash welded rings shall be heat treated as follows; pyrometry shall be in accordance with AMS 2750.

Solution Heat Treatment

When solution heat treatment is used, heat to a temperature within the range 50 to 150°F (28 to 83°C) degrees below the beta transus, hold at the selected temperature within ±25°F(±14°C) for a time commensurate with section thickness and the heating equipment and procedure used, and cool at a rate equivalent to an air cool or faster.

Annealing

Heat to a temperature within the range 1300 to 1450 °F (704 to 788 °C),hold at the selected temperature within ±25°F(±14°C) for not less than 1 hour, and cool as required.

Application

These products have been used typically for parts requiring moderate strength with a maximum service temperature in the 750 to 900 °F (399 to 510 °C) range depending on time at temperature where the product is to be used in the annealed condition, but usage is not limited to such applications.

MONO Group is one of Titanium and Titanium alloy manufacturer&Supplier&Wholesaler from China,We can supply ASTM /DIN/ISO/GB/AMS stndard high quality Titanium plate,sheet,round bar,wires,tube.pipes,fittings,flange,pls contact us freely for your RFQ to info@monokj.com